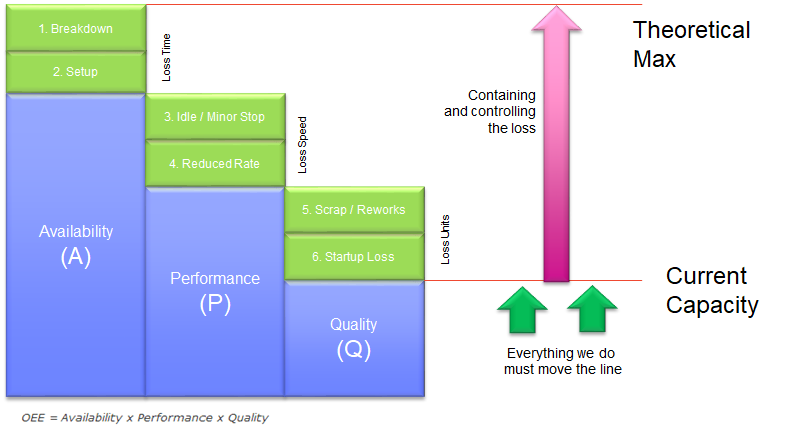

All manufacturers are always eager to be able to produce high-quality products or services. Maintaining or even improving standards and at the same time reducing the rework process is the target to be achieved by companies in general. Several factors are used to assess a company in its efforts to achieve and maintain this standard, those are Availability, Performance, and Quality assessment.

I. Availability

Availability can be elaborated as factories or their tools (equipment, engines, assets) have their own limited operational time. All tools in factories are surely not operated all day long. Obviously, in one week, the equipment cannot operate for more than 7x 24 hours this is the case when the needed equipment is endlessly operated during that period.

There is also equipment in factories according to its normal usage do not need to be operated 24x7, i.e. HVAC is needed in daylight/office hours only.

If a machine is requested and able to operate for 24 hours every day, it can be said that the machine's availability is 100%. For the Air Conditioner case above, if the Air Conditioner needs to be operated for 8 hours, but because it also needs maintenance for two hours the availability rate of the Air Conditioner on that day is 6/8 or 75%. In brief, the availability factor is related to operational time.

Factors that can reduce availability rate:

- Breakdown (No 1 in Picture 1) and

- Setup (No 2 in Picture 1)

Breakdown means obstruction or damage. If there is a breakdown, it obviously reduces the operational time of the machine. The second factor is setup, which is the installation of the equipment for the first time, which includes starting the machine (also for the first time). The setup time obviously reduces the operational time. This implies that the activity of changing and replacing a machine will reduce the machine's availability.

Maintenance and asset management are aimed to reduce breakdowns and the setup process, which will improve the availability rate. With a high availability rate, a higher number of products will be produced as well as earn more income.

II. Performance

The second factor is Performance. The phrase "operational engine" and "operational engine in full speed" are two phrases that have different meanings. Operational machines with maximum speed will produce products as much as they can. The maximum speed cannot be achieved if there is a breakdown or wear and tear in the machine. On the other side, there is a tactic to extend/prolong the machine lifetime by maintaining the machine's speed to medium speed.

The other case that can interfere with the machine's speed is when the machine is often experiencing a "cough" or can be represented in the picture as idle/minor stop.

III. Quality

The third factor is quality. A machine's breakdown can also cause low-quality products or damaged products. Having damaged products can initiate the rework process the rework activity to fix the damages. The more damaged products, the higher the cost that must be burdened to a factory. Repeated machine replacement often can make products that are produced at the machine setup for the first time become low-quality products or below the expected specifications.

A company is called a world-class company if its Availability X Performance X Quality = OEE (Overall Equipment Effectiveness) is 85%. The figure 85% is derived from the availability of 90% with a performance of 95% and quality of 99%.

The gap between the current capacity that is represented by the below red line (Picture 1) and maximum condition (the above red line) is improvement potential for such a company.

The potency is directly proportional to the number of quality products that can be produced. Moving the bottom red line upward means increasing the Availability, Performance, and Quality rate respectively while bearing in mind the upper limit of each respective factor.

The problem lies in the production demand that keeps increasing. It is worried that the existing production machines at a certain moment cannot afford to fulfill the request so that it can cause opportunity loss of the company to increase its income. To overcome the problem, there are several alternatives. One of them is by taking advantage of the existing manufacturing system through an alternative operational system or increasing the amount of production according to the company's need.

If the increase of production number can be performed by building new factories then the increase of Availability, Performance, and Quality rate can be achieved by finding a hidden factory. Of course, discovering a hidden factory has a very meaningful added value because it will greatly reduce cost in contrast of building a new factory.

The implementation of EAM (Enterprise Asset Management) such as IBM Maximo is a part to begin the discovery of the hidden factory.

SHARE POST:

Maximo industry solutions

Maximo helped DC Water save USD 1 million by making smarter asset deployment decisions, all while driving better outcomes for customers

Learn MoreRelated Blog

.png)